Home » Blog » Blog » Multimedia & Vision Engineering » Importance of VLSI Design Verification and its Methodologies

Importance of VLSI Design Verification and its Methodologies

In the dynamic world of VLSI (Very Large-Scale Integration), the demand for innovative products is higher than ever. The journey from a concept to a fully functional product involves many challenges and uncertainties where design verification plays a critical role in ensuring the functionality and reliability of complex electronic systems by confirming that the design meets its intended requirements and specifications. In 2023, the global VLSI market is expected to be worth USD 662.2 billion, according to Research and Markets. According to market analysts, it will be worth USD 971.71 billion in 2028, increasing at a Compound Annual Growth Rate (CAGR) of 8%.

In this article, we will explore the concept of design verification, its importance, the process involved, the languages and methodologies used, and the future prospects of this critical phase in the development of VLSI design.

What is design verification and its importance?

Design verification is a systematic process that validates and confirms that a design meets its specified requirements and sticking to design guidelines. It is a vital step in the product development cycle, aiming to identify and rectify design issues early on to avoid costly and time-consuming rework during later stages of development. Design verification ensures that the final product, whether it is an integrated circuit (IC), a system-on-chip (SoC), or any electronic system, functions correctly and reliably. SoC and ASIC verification play a key role in achieving reliable and high-performance integrated circuits.

VLSI design verification involves two types of verification.

- Functional verification

- Static Timing Analysis

- Identification and preparation: At this stage, the design requirements are identified, and a verification plan is prepared. The plan outlines the goals, objectives, and strategies for the subsequent verification steps.

- Planning: Once the verification plan is ready, the planning stage involves resource allocation, setting up the test environment, and creating test cases and test benches.

- Developing: The developing stage focuses on coding the test benches and test cases using appropriate languages and methodologies. This stage also includes building and integrating simulation and emulation environments to facilitate thorough testing.

- Execution: In the execution stage, the test cases are run on the design to validate its functionality and performance. This often involves extensive simulations and emulators to cover all possible scenarios.

- Reports: Finally, the verification process concludes with the generation of detailed reports, including bug reports, coverage statistics, and an overall verification status. These reports help in identifying areas that need improvement and provide valuable insights for future design iterations.

- Startpoint: The startpoint of a timing route is where data is launched by a clock edge or is required to be ready at a specific time. A register clock pin or an input port must be present at each startpoint.

- Combinational Logic Network: It contains parts that don’t have internal memory. Combinational logic can use AND, OR, XOR, and inverter elements but not flip-flops, latched, registers, or RAM.

- Endpoint: This is where a timing path ends when data is caught by a clock edge or when it must be provided at a specific time. At each endpoint, there must be an output port or a pin for register data input.

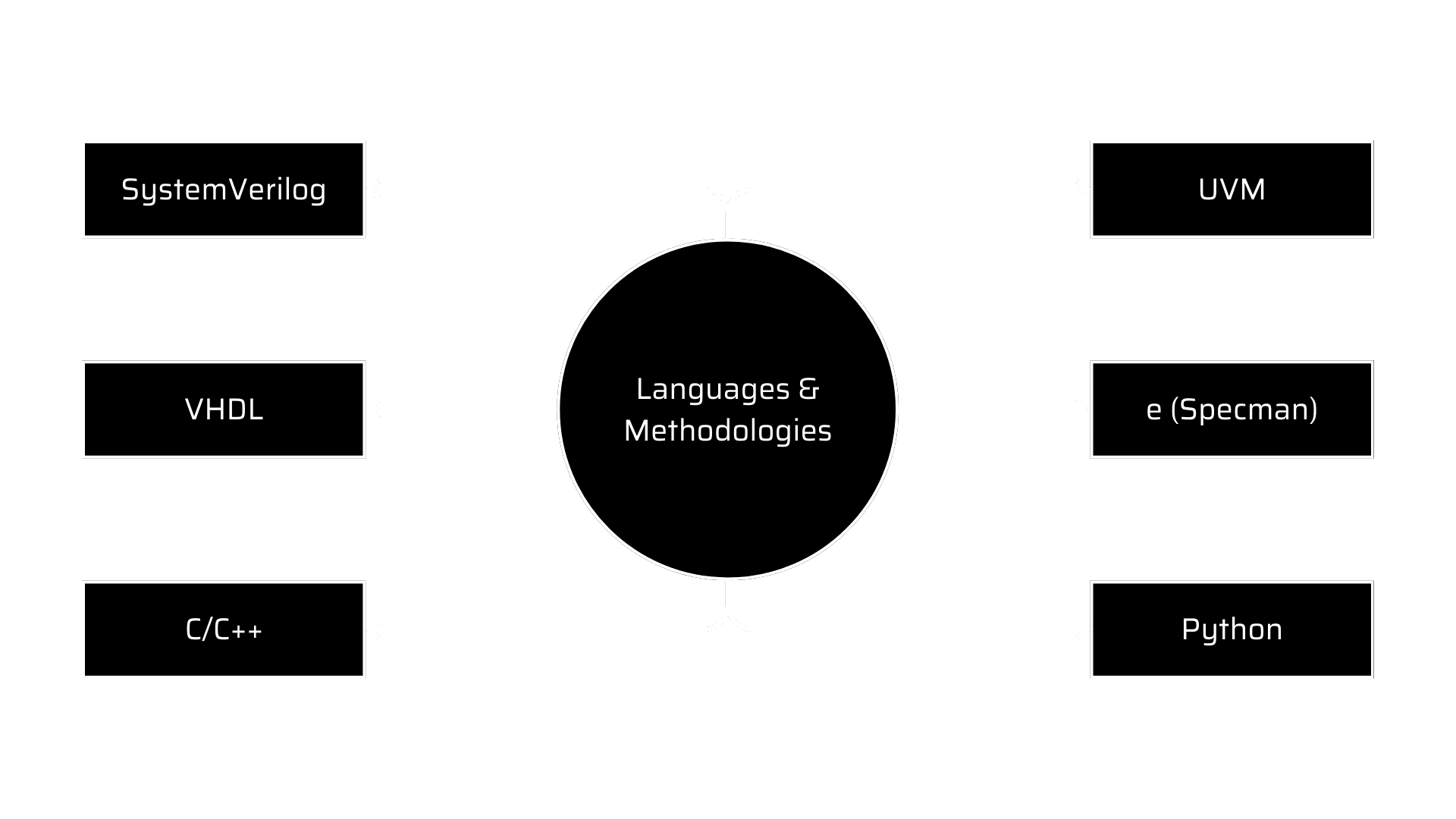

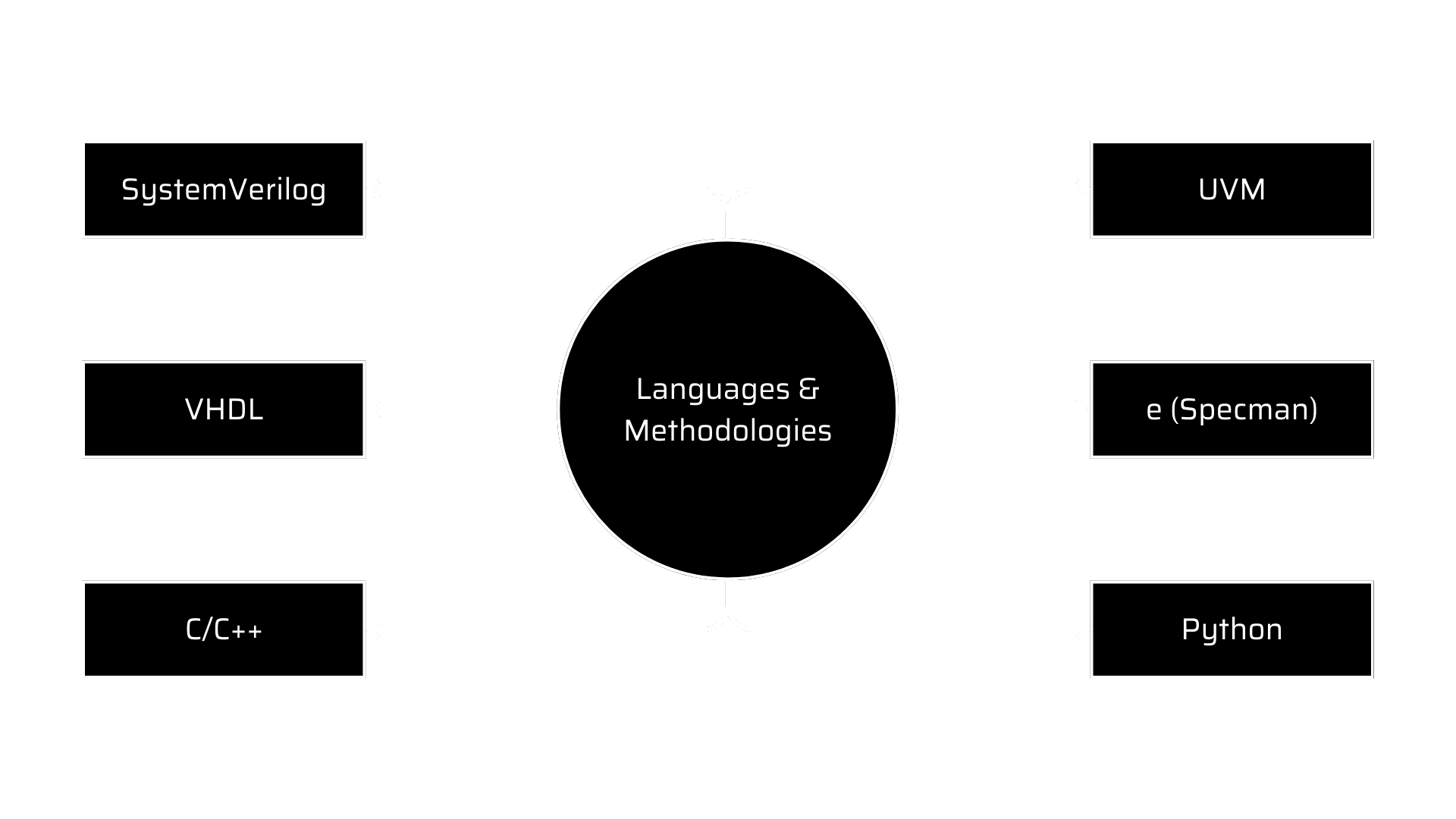

- SystemVerilog (SV) verification: SV provides an extensive set of verification features, including object-oriented programming, constrained random testing, and functional coverage.

- Universal Verification Methodology (UVM): UVM is a standardized methodology built on top of SystemVerilog that enables scalable and reusable verification environments, promoting design verification efficiency and flexibility.

- VHDL (VHSIC Hardware Descriptive Language): VHDL is widely used for design entry and verification in the VLSI industry, offering strong support for hardware modelling, simulation, and synthesis.

- e (Specman): e is a verification language developed by Yoav Hollander for his Specman software that offers powerful verification capabilities, such as constraint-driven random testing and transaction-level modelling. Later it was renamed as Verisity which was acquired by Cadence Design Systems.

- C/C++ and Python: These programming languages are often used for building verification frameworks, test benches, and script-based verification flows.

VLSI design verification languages and methodologies

Advantages of design verification Effective design verification offers numerous advantages to the VLSI industry.- It reduces time-to-market for VLSI products

- The process ensures compliance with design specifications

- It enhances design resilience to uncertainties

- Verification minimizes the risks associated with design failures

Author

-

Ambuj is a Marketing professional at MosChip creating impactful techno-commercial writeups and conducting extensive market research to promote businesses on various platforms. He has been a passionate marketer for more than three years and is constantly looking for new endeavours to take on. When He’s not working, Ambuj can be found riding his bike or exploring new destinations.