Functional Safety 101: A Primer on ASIL Classification under ISO 26262

Modern vehicles are continuously evolving with complex electronic and connected systems, where the vehicle itself is becoming intelligent and playing an active role in assisting the driver in various ways. These systems play a key role in enabling safety and providing great connected user experience. However, the failure of these systems can cause severe safety risks. This is why electronic systems in a vehicle require standardization and a structured way to evaluate safety-critical systems.

To standardize these systems, we have regulatory standards that help us define risks identify, mitigate, and manage them. ISO 26262 is a global standard for on road vehicles and helps in assessing the risk factor associated with various automotive systems. Though there are various components of the ISO 26262, we will be specifically discussing Automotive Safety Integrity Level (ASIL).

What is the Role of ASIL?

ASIL is a key component of the ISO 26262 functional safety standard which can be defined as a risk classification scheme. It assesses automotive systems for potential hazards by performing a risk analysis based on three factors- Severity, Exposure, and Controllability. Let’s try to understand each of these factors.

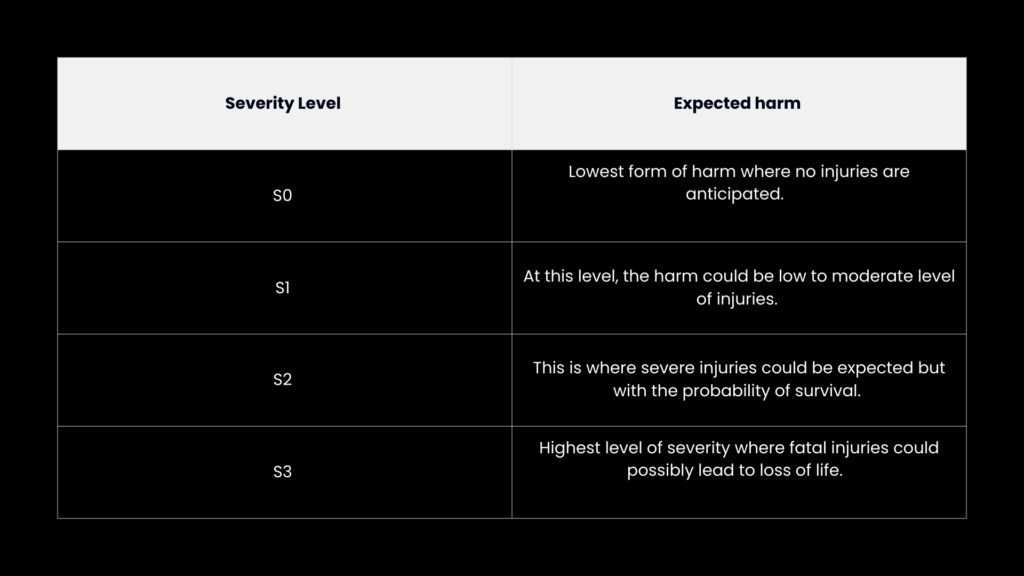

Severity (S): Defining the extent of the harm caused by failures. Each of these factors have different levels of severity based on the level of harm:

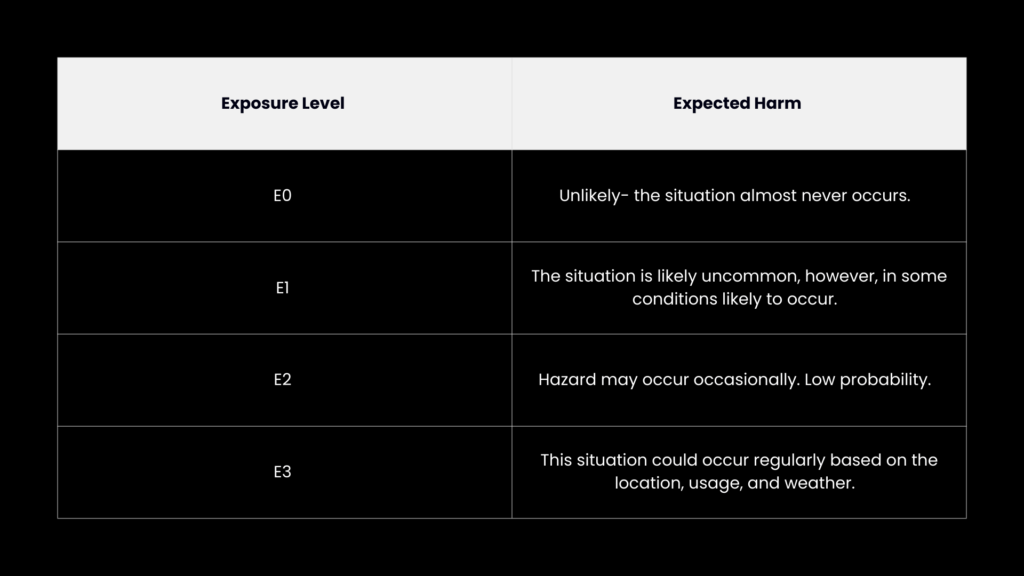

Exposure (E): The likelihood of the vehicle encountering the conditions during which the hazard could occur.

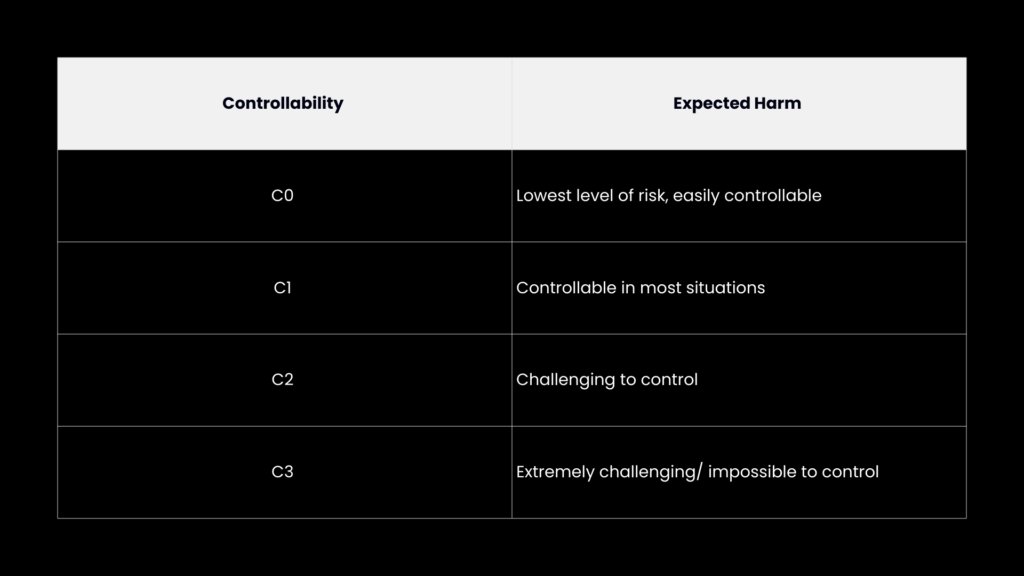

Controllability (C): The ability of the driver to be in control or regain control to prevent harm to themselves and other vehicles on the road.

The risk factor is determined based on the above-mentioned factors and then classified at any level from ASIL-A to ASIL-D. ASIL-A is the lowest level of safety requirement, and ASIL-D being the highest level of safety requirements.

Have you ever thought of the future of functional safety in an era of software defined vehicles?

Check out what our expert has to say: Read Now

How Do You Determine ASIL?

The first step in determining ASIL is to evaluate the associated risks which may cause a hazard. This is done by performing Hazard Analysis and Risk Assessment (HARA).

To understand this more clearly, let’s see a couple of combinations. Let’s assume where a combination of S3, E4, and C3, then based on the table, this would be considered as a highly hazardous scenario. So, this requires stringent safety requirements.

On the other hand, S0, E1, and C1 would not require safety protocols to be addressed under ISO 26262.

Now that we have talked about the extremes, a combination such as S2, E3, C2 could be classified under ASIL-C.

Under the functional safety standards, safety goals are considered more critical than functionality. The main purpose of ISO 26262 is to define functional safety as the absence of hazards caused by risks or to avoid unreasonable risks.

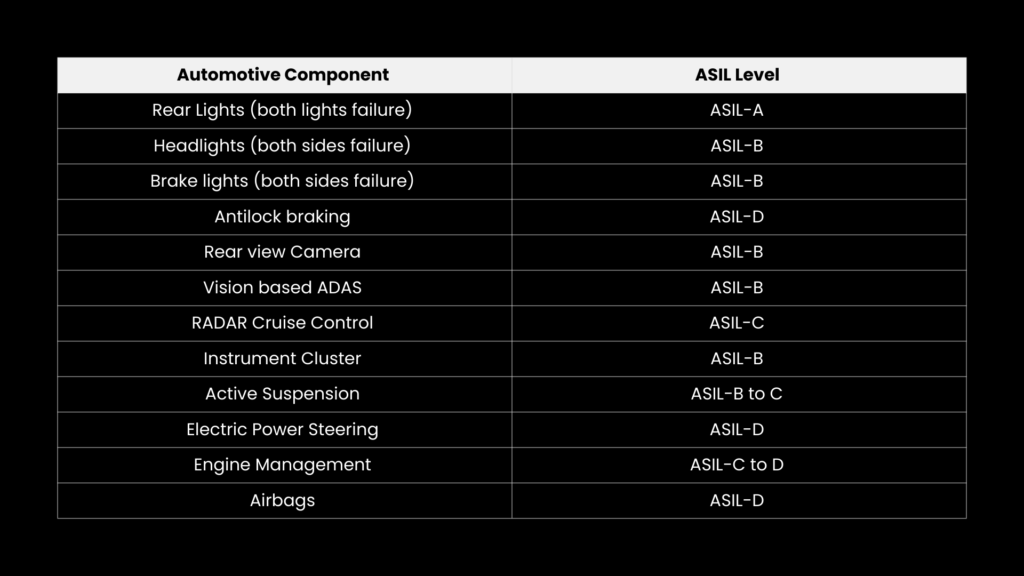

Let’s try to classify some of the components in our vehicles and where they stand in the ASIL classification.

ASIL determination helps in creating reliable and safe automotive functionality, which in turn produces great user experience. However, implementing ASIL has its own sets of challenges. Let’s take a look at some of them.

Challenges in ASIL Implementation

Evolving Complex Systems: The role of software is evidently increasing with the advent of modern systems, Software Defined Vehicles (SDV), centralized architecture, etc., which makes defining safety even more challenging.

Identifying Hazards and Risks Accurately: Evaluating risks and hazards based on Severity, Exposure, and Controllability requires high expertise. So, it is important to identify the right individuals across teams that can help you with accurate assessment. You need to have adequate training for your team to implement reliable ASIL implementation.

Scalability: Sometimes automotive manufacturers scale their systems across different models and variants without doing proper safety analysis, which may cause issues. So, one needs to be careful at all times with the implementation of systems and how they react in real-world scenarios.

Extensive Documentation: Implementing ASIL requires constantly maintaining extensive documentation. Keeping these documentations up to date with changes taking place during the development stage is a tedious task.

Third party Integration: Integration of third-party software or hardware that may not have undergone ASIL classification becomes difficult to integrate. Also, necessary documentation may not be readily available to validate it.

Best Practices in Implementing Functional Safety

Integration in Concept Phase: If you are designing an automotive system, it is best to consider functional safety right from the ideation or concept stage, instead of having to implementation during design or prototyping and derail the entire development process.

Define Your Goals: Define safety goals into specific proper technical safety requirements. There should be traceability across the development process.

Document Every Step: This is important for any ISO standard that you wish to implement. It is important to document the entire process for traceability and come in handy during ISO and internal audits. This will help you to reduce non-conformities.

Review Process: Continuous assessment as the system is being developed will also help you ensure safety. Conduct regular audits and assessments to identify gaps and non-conformities.

Include Inter-disciplinary Teams: Assemble a team of experts from across different teams along with your safety experts. All aspects of the system can then be considered from each team’s perspective.

Wrapping Up

While it’s challenging to implement ASIL with modern architectures and systems, adopting best practices and integration of functional safety early into the design and development process will help you to address it effectively. On top of this, regular internal audits can help you set effective processes to deliver world-class products which are compliant with industry standards.

Train your team to think that functional safety is not just a standard to be achieved but it’s about building trust with your customers with every ride. Adhering to quality standards should become part of your engineering culture.

MosChip is a Product and Silicon Engineering company with over 25 years of experience and has delivered over 500 projects globally. We engineer connected systems from ideation and concept to low-volume manufacturing with in-house IPs and accelerators that help in accelerating time to market.

Our end-to-end product engineering capabilities are aimed at delivering innovative, reliable, connected, and scalable products and solutions across markets. MosChips specializes in delivery connected automotive subsystems and adheres to functional safety standards. Our team of experts has experience working with adaptive AUTOSAR, FuSa (ISO 26262), and MISRA C compliances.

To know more about our automotive expertise, please schedule a call today with our team.

Author

-

Smishad Thomas is a Technical Marketing Manager at MosChip. He has over 13 years of experience in technology marketing, branding, and content leadership. He has a keen interest in product engineering and loves developing convincing stories that translates technical innovations into clear, engaging messaging that resonates with business audiences