Revolutionizing Supply Chain Management with the Power of AIoT

In today’s fast-paced and interconnected world, the supply chain landscape is undergoing a significant transformation driven by integrating advanced technologies. Central to this transformation is the concept of the Artificial Intelligence of Things (AIoT), which combines Artificial Intelligence (AI) with the Internet of Things (IoT). AIoT is becoming increasingly important in modern supply chain management, offering businesses enhanced efficiency, real-time insights, and smarter decision-making capabilities. As supply chains adapt to growing complexities, the role of AIoT is pivotal in ensuring that operations are agile, responsive, and optimized for performance.

Integrating AI and IoT transforms supply chains by leveraging IoT devices with embedded sensors to capture critical data across various stages. AI processes this data to deliver actionable insights, predictive analytics, and automation capabilities. This synergy drives greater operational efficiency by enhancing real-time visibility, optimizing logistics, and improving overall performance. In this discussion, we will delve into how AIoT refines supply chain management, emphasizing key benefits like enhanced transparency, smarter decision-making, and process automation. Practical examples will highlight its impact, making it a vital tool for businesses aiming to stay competitive in today’s dynamic markets. Embracing AIoT innovations is essential for shaping the future of supply chain ecosystems.

Understanding AIoT in Supply Chain Context

AIoT is an ecosystem convergence that enables smart devices to perform advanced analytics and make informed decisions based on data collected from various sources, thereby enhancing operational efficiency across supply chains. It comprises several critical components, including:

- Sensors: IoT devices with sensors like temperature, proximity, GPS trackers, etc., gather real-time data on parameters such as temperature, humidity, location, and motion from the physical environment, enabling companies to monitor assets and processes efficiently.

- Data Analysis: In AIoT for the supply chain, data is analyzed using advanced AI algorithms such as machine learning and deep learning to process IoT sensor data. These algorithms convert raw data into insights for demand forecasting, predictive maintenance, and anomaly detection, improving efficiency and decision-making in supply chain operations.

- Connectivity: This component ensures seamless data transmission between devices, platforms, and users. Reliable connectivity options, including cellular, Wi-Fi, and satellite, are essential for real-time monitoring and management of supply chain operations, allowing stakeholders to access and act on information promptly.

AIoT transforms the supply chain by replacing isolated systems and manual processes. Unlike conventional chains, AIoT integrates AI devices for monitoring, analysis, and automation. This integration offers several advantages over conventional methods:

- Real-time Insights: Unlike traditional technologies that may delay information processing, AIoT systems provide immediate access to critical data, enhancing supply chain visibility, and improving demand forecasting and responsiveness.

- Predictive Capabilities: Traditional supply chains often use historical data for planning, which can lead to inefficiencies. In contrast, AIoT harnesses predictive analytics to anticipate demand fluctuations and operational challenges, allowing businesses to adapt proactively.

- Enhanced Automation: With AIoT, automation goes beyond simple task execution; it encompasses intelligent processes, such as optimizing inventory levels and identifying maintenance needs before they escalate into failures

Impact of AIoT on Supply Chain Efficiency and Responsiveness

The integration of AIoT in supply chain operations significantly enhances both efficiency and responsiveness. Companies leveraging AIoT technologies can experience:

- Increased Operational Efficiency: By automating routine tasks and enabling real-time monitoring, AIoT reduces manual errors and speeds up processes such as order fulfilment and inventory management. This efficiency translates into lower operational costs and improved service levels.

- Improved Supply Chain Visibility: AIoT provides end-to-end visibility across the supply chain, enabling organizations to track inventory and assets in real time. This transparency helps in avoiding stockouts or overstock situations, ultimately optimizing inventory management.

- Swift Adaptation to Market Conditions: The ability to analyze data from various sources allows companies to make informed decisions rapidly. For instance, in the event of supply chain disruptions, AIoT systems can assist managers in formulating contingency plans based on real-time insights, thereby minimizing delays and losses.

Applications of AIoT in Supply Chain Operations

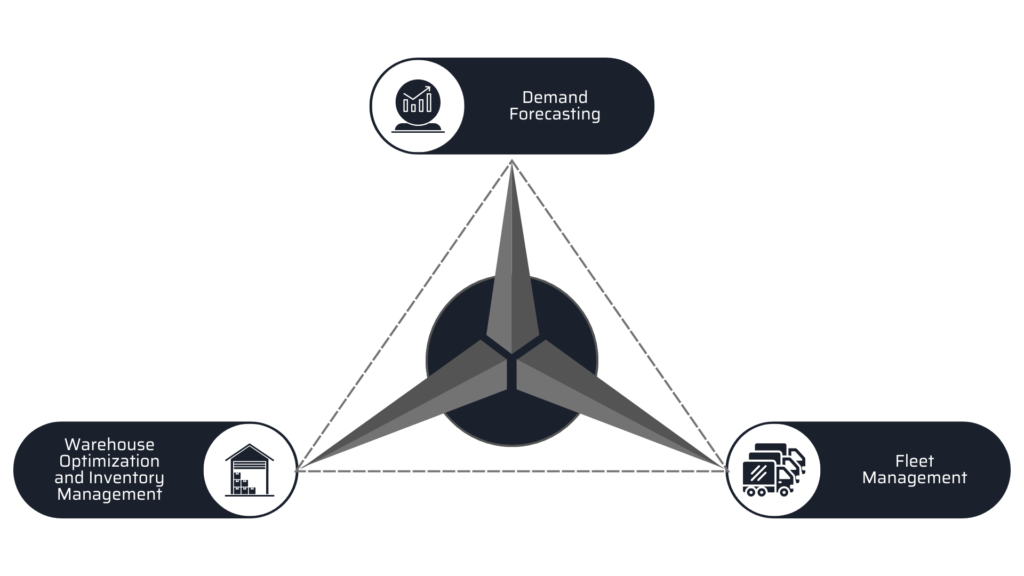

AIoT enables real-time tracking of goods, predictive maintenance of equipment, and demand forecasting in supply chain operations. It enhances efficiency by automating processes, reducing downtime, and optimizing inventory management for improved operational performance.

- Demand Forecasting: AIoT-driven demand forecasting enhances supply chain efficiency by leveraging IoT sensors and AI analytics to gather and analyze data from stores, warehouses, and distribution centers. This enables businesses to detect demand trends, seasonal variations, and market shifts, ensuring accurate product demand forecasts. Predictive insights help optimize inventory levels, improve production planning, and respond quickly to market changes, minimizing stock issues and ensuring product availability. These advancements enhance operational efficiency, and boost customer satisfaction by delivering products on time, strengthening brand loyalty, and maintaining market competitiveness.

- Fleet Management: AIoT integration in fleet management enhances efficiency, and boosts customer satisfaction by enabling real-time vehicle tracking through GPS sensors. Logistics managers gain transparency to adjust routes and schedules based on real-time data, while AI algorithms optimize routes by analyzing traffic, weather, and delivery history, minimizing delays and cutting fuel costs. Predictive maintenance ensures vehicle reliability, and sensors provide insights into fuel usage and driving habits, allowing businesses to promote efficient practices. These advancements streamline operations, improve safety and compliance, and create a reliable supply chain.

AIoT Application in Supply Chain Operations

- Warehouse Optimization and Inventory Management: AIoT is revolutionizing warehouse operations and inventory management by integrating advanced IoT sensors, such as RFID tags and Bluetooth devices, with intelligent AI algorithms to create dynamic, highly efficient environments. Real-time inventory tracking ensures continuous visibility into stock levels, enabling businesses to optimize inventory management, reduce holding costs, and prevent overstock or stockouts. AI-driven systems automate core processes, including storage location optimization, precise pick-and-place operations, and replenishment predictions, delivering unparalleled accuracy and operational efficiency. Real-time asset and goods tracking minimizes retrieval times and operational errors, boosting productivity and reliability. Predictive analytics further enhance risk mitigation, reduce waste, and improve inventory accuracy. The combination of automated replenishment and predictive stock management reduces discrepancies and enhances flexibility, allowing remote inventory control and better resource allocation. Full data visibility empowers faster, data-driven decision-making, timely order fulfilment, and superior customer satisfaction. These innovations streamline operations, optimize operational cost, and improve product availability while intelligent layout optimization and resource planning strengthen overall supply chain resilience and responsiveness, achieving unmatched operational excellence in today’s competitive landscape.

Altogether, AIoT integration in supply chain management combines IoT’s real-time data with AI’s analytics, enhancing efficiency, agility, and responsiveness. It improves visibility, enabling real-time inventory, assets, and conditions monitoring, while AI-driven predictive analytics optimizes demand forecasting. AIoT automates tasks, streamlines processes, and reduces errors, improving resource utilization and customer satisfaction. By adapting to market changes and customer needs, AIoT transforms supply chain operations, minimizing waste, and improving service delivery.

MosChip’s AIoT-driven supply chain management expertise empowers businesses to enhance efficiency, visibility, and responsiveness through customized and scalable solutions. Utilizing semiconductor design strengths, low-power embedded systems, and secure communication protocols like Wi-Fi, Bluetooth, Cellular, and LoRa, MosChip enables real-time data capture across supply chain operations. Combined with AI-powered analytics, these solutions optimize inventory management, predictive maintenance, and logistics planning. By integrating intelligent automation and advanced connectivity, MosChip helps build resilient, adaptive supply chains capable of meeting dynamic market demands and delivering superior performance.

Author

-

Darshil is a Marketing professional at MosChip creating impactful techno-commercial writeups and conducting extensive market research to promote businesses on various platforms. He has been a passionate marketer for more than four years and is constantly looking for new endeavors to take on. When He’s not working, Darshil can be found reading and playing guitar.