Harnessing Intelligent Automation for Enhanced Product Manufacturing

Intelligent Automation is seen as an optimistic innovation for manufacturers in the current competitive market. It combines different intelligent methods to optimize manufacturing processes by allowing systems to perform repetitive tasks, gather and analyse data, learn from the data, and make informed decisions. Intelligent Automation serves as a critical enabler for digital transformation, helping manufacturers build smart factories that are agile, efficient, and can adapt to changing demands. Currently, the manufacturing industry faces challenges like labour shortages, supply chain disruptions, and rising costs which can be mitigated by innovating processes and workflows through Intelligent Automation.

The Intelligent Process Automation market is expected to grow significantly, from $16.2 billion in 2024 to $42 billion by 2032, representing a Compound annual growth rate (CAGR) of over 12.6%

Importance of Intelligent Automation in the Manufacturing Industry

Intelligent Automation backed by technologies like AI, ML, RPA, and IoT are crucial for product manufacturing companies. They can significantly:

- Improve operational efficiency and precision in timing

- Increase product quality

- Automate repetitive tasks to optimize production processes

- Enable real-time monitoring and predictive maintenance

- Increase flexibility to respond quickly to changing demands and preferences

Overall, it improves resource allocation, data analysis, sustainable growth, innovation, and competitiveness in the changing environment.

How Different Technologies under Intelligent Automation Enhances Product Manufacturing

Artificial Intelligence (AI) and Machine Learning (ML)

Artificial Intelligence and Machine Learning enhance manufacturing processes by analyzing large data sets, enabling predictive analytics, improving maintenance, and planning, and continuously refining operations for real-time efficiency.

There are some topologies associated with AI/ML on the Manufacturing side:

- Edge AI Computing: Predictive maintenance powered by edge AI computing technology substantially enhances product manufacturing by enabling real-time monitoring and analysis of equipment performance directly on the factory floor. By integrating IoT sensors that collect data on parameters such as temperature, vibration, and humidity, edge computing processes this information locally, allowing for near-instant detection of anomalies that may indicate potential failures. This approach minimizes unnecessary maintenance and breakdowns.

- Natural Language Processing (NLP): Natural Language Processing (NLP) can analyse maintenance logs and equipment reports. One of the NLP algorithms named Latent Dirichlet Allocation (LDA) helps in categorizing maintenance requests or logs by identifying underlying topics present in the textual data. This can assist in spotting common failure trends and recurring issues, ultimately aiding in early diagnosis and prevention which improves overall operational efficiency.

- Computer Vision: Computer vision techniques improve product manufacturing by enhancing quality control, inspection, and automation through real-time defect detection, thus reducing labour costs and improving efficiency.

Robotic Process Automation (RPA)

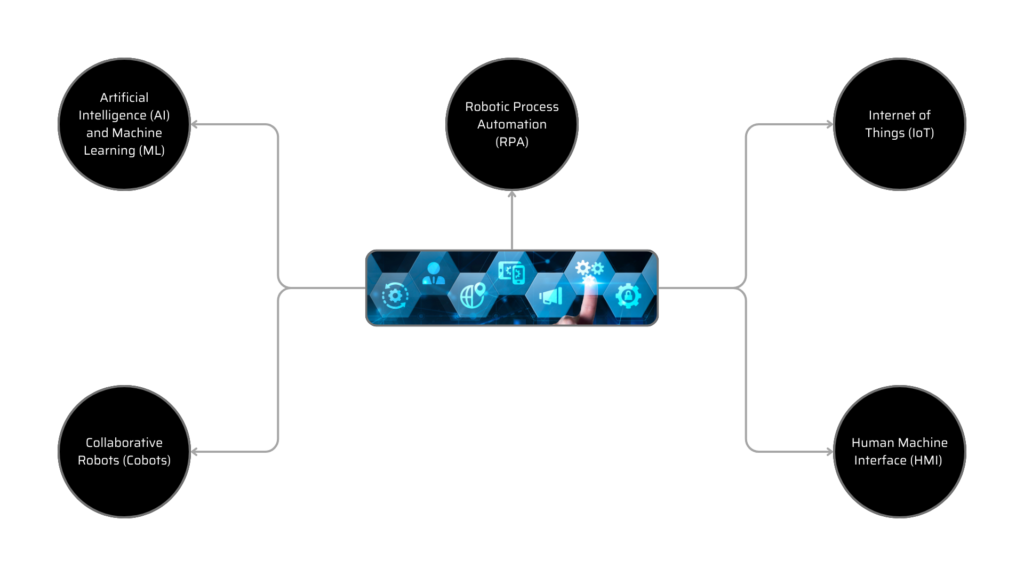

Intelligent Automation Technologies for Product Manufacturing

Internet of Things (IoT)

Collaborative Robots (Cobots)

Human Machine Interface (HMI)

Functions Impacted by Intelligent Automation in Product Manufacturing

Intelligent Automation technologies have various areas of application in the product manufacturing sight. Intelligent Automation revolutionizes production and assembly lines through RPA and cobots which improves the operational efficiency of lines. Also, supply chain management is enhanced by utilizing predictive analytics, automated workflow, and optimizing inventory as automated reordering processes help maintain optimal stock levels by generating purchase orders when inventory falls below predetermined thresholds, thereby minimizing the risk of stockouts.

Siemens implemented Intelligent Automation technologies like IoT, AI, and digital twins at its Amberg Electronics Plant which transformed it into a smart factory. This resulted in significantly higher efficiency and quality with productivity. Toyota also adopted robotic process automation to automate repetitive tasks like parts ordering and inventory management. This improved operational efficiency with reduced errors.

Harnessing Intelligent Automation in product manufacturing offers a multitude of advantages that can significantly transform operations. To summarize, key benefits include increased efficiency and productivity through the automation of repetitive tasks, which streamlines workflows and reduces cycle times. Furthermore, Intelligent Automation enables flexibility in production processes, allowing manufacturers to swiftly adapt to evolving markets and customize products as needed. Together, these benefits position manufacturers for sustained growth and competitiveness in an increasingly dynamic marketplace.

Author

-

Darshil is a Marketing professional at MosChip creating impactful techno-commercial writeups and conducting extensive market research to promote businesses on various platforms. He has been a passionate marketer for more than four years and is constantly looking for new endeavors to take on. When He’s not working, Darshil can be found reading and playing guitar.