Enhancing Efficiency with Advanced Asset Monitoring Solution

In today’s dynamic business landscape, effective asset management has become crucial for organizations striving to optimize operations and maintain a competitive edge. Asset monitoring solutions are crucial for businesses to track, manage, and use valuable assets like machinery, vehicles, and inventory efficiently. As enterprises rely more on technologies such as IoT sensors, RFID, GPS, BLE, Ultra-Wideband (UWB), etc. for asset management, efficient practices are crucial. Neglecting proper asset monitoring can lead to lost items, high maintenance costs, and compliance problems. Investing in advanced monitoring solutions enhances efficiency and streamlines operations.

Effective asset management impacts different efficiencies – operational, maintenance, asset, and energy, that are vital for optimizing management strategies. Operational efficiency ensures full asset utilization, reducing waste and improving productivity. Maintenance efficiency minimizes downtime and repair costs through predictive strategies, extending the asset lifespan. Asset efficiency involves resource tracking, and energy efficiency targets reducing energy consumption for cost and sustainability goals. These efficiencies streamline operations, improve decision-making, and create a competitive advantage.

Understanding Advanced Asset Monitoring

Advanced asset monitoring solutions utilize modern technology involving IoT sensors, RFID, Geographic Information System (GIS), BLE, Cloud Computing to offer real-time insights into an organization’s asset landscape. They enable businesses to track assets, collect data, analyze trends, and make proactive decisions. Traditional asset management often uses manual processes like spreadsheets and paper logs, causing inefficiencies, inaccuracies, and a lack of real-time visibility. These systems are limited in functionality, resulting in lost assets, delayed maintenance, and compliance challenges.

Real-time insights help businesses detect issues promptly, enabling proactive responses and reducing unexpected failures. Monitoring in real-time enhances visibility and control, optimizing asset utilization and operations, and empowering managers with immediate insights for data-driven efficiency improvements.

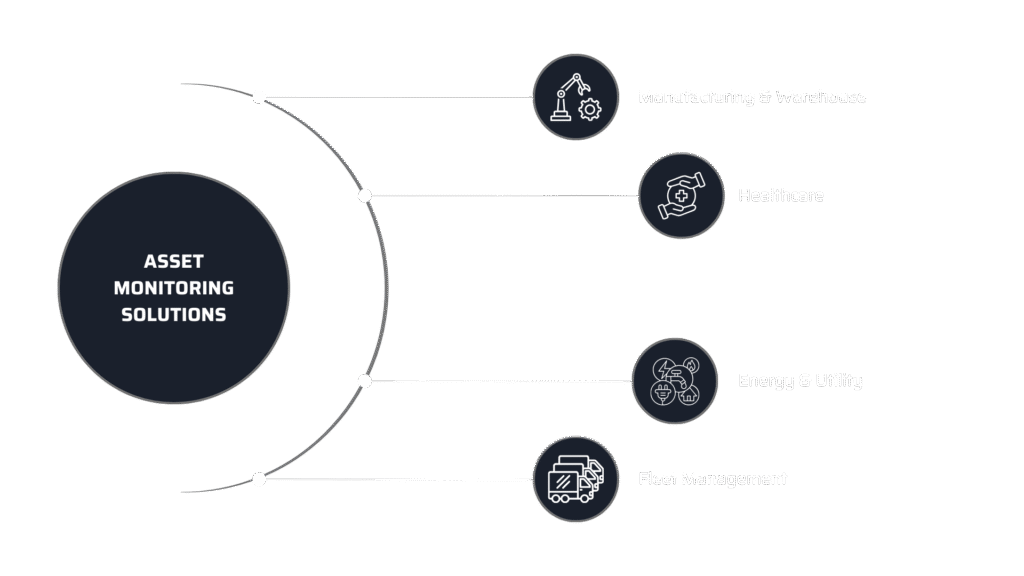

Advanced Asset Monitoring Solutions in Various Industries

Manufacturing and Warehouses

Modern manufacturing facilities use advanced asset monitoring systems with IoT sensors to collect data from machinery. These systems track various parameters like temperature, vibration, humidity, and usage patterns. Predictive maintenance analyzes this data to preempt equipment failures, enabling proactive scheduling, and minimizing unexpected downtime.

Maintenance efficiency is one of the most significant benefits of advanced asset monitoring in manufacturing. Advanced asset monitoring enhances maintenance efficiency by enabling predictive maintenance through real-time data analysis, unlike traditional maintenance methods like breakdown-based, condition-based that rely on scheduled or reactive approaches, potentially reducing costs and production disruptions.

Asset efficiency maximizes resource utilization through advanced monitoring technologies that offer insights into asset performance for improved resource allocation. Analysis of machine output and operational patterns helps identify underperforming assets for corrective action.

The warehouse sector is vital for supply chains, managing storage, and goods movement. To enhance efficiency, asset monitoring technology like IoT sensors and RFID, BLE is crucial. These tools offer real-time visibility and process optimization, leading to improving asset and maintenance efficiency.

Operational efficiency is emphasized by advanced asset monitoring solutions in warehouses for real-time inventory and equipment tracking, ensuring proper storage, picking, and dispatch. This technology reduces manual tracking errors, speeds up operations, minimizes order fulfillment delays, and boosts overall productivity.

Some warehouse resources, such as forklifts, conveyor belts, and other equipment, are optimally utilized. Telematics and monitoring tools can track how equipment is used, identifying areas where resources may be underutilized or overused. This data can help managers redistribute tasks and workload more efficiently, which enhances asset efficiency.

Healthcare

The healthcare industry is highly reliant on the efficient management and utilization of medical equipment, facilities, and other critical assets. To ensure optimal patient care and cost-effective operations, healthcare providers are increasingly adopting advanced asset monitoring technologies. These systems leverage RFID, real-time location systems (RTLS), and predictive analytics to provide detailed insights into asset performance, availability, and condition.

Asset efficiency maximized by asset monitoring tools track medical equipment usage to identify underutilized or aging assets. This data helps healthcare providers make informed decisions on reallocating or upgrading equipment to maximize investments.

Real-time asset monitoring ensures medical equipment availability for patient care and emergencies by tracking devices like ventilators and infusion pumps. Automated inventory management maintains stock levels, enhancing operational efficiency and patient outcomes.

Asset Monitoring Solutions for Various Industries

Energy and Utility

The energy and utility sectors depend on vital infrastructure to provide services like electricity, water, and gas. With rising demand and aging systems, there’s a growing need for improving efficiency and downtime prevention. Advanced asset monitoring technologies like Supervisory Control and Data Acquisition (SCADA) and Geographic Information System (GIS) are now pivotal, helping companies oversee and enhance their assets in real-time.

In energy and utility industries, key machinery such as turbines, transformers, and pipelines are critical. Unexpected downtime can cause expensive repairs and service disruptions. Companies can use SCADA or GIS and IoT sensors to monitor equipment condition in real time, receiving early warnings of potential failures through tracking metrics like vibration, temperature, and pressure.

Maintenance efficiency enlarges by such a proactive strategy, allowing for timely repairs, prolonging asset lifespan and cutting maintenance expenses.

Energy efficiency is crucial in energy and utility sectors. Asset monitoring is important for optimal operation of power plants, wind farms, and distribution networks. SCADA track energy usage, detects inefficiencies, and guide decisions for reducing consumption and emissions through real-time data and AI analytics.

Fleet Management

Fleet management systems utilize advanced technologies like IoT, GPS, telematics, and predictive analytics for real-time monitoring of vehicle location, driver behavior, fuel usage, and engine health. IoT sensors offer live updates on key components such as tires, brakes, and engines, allowing for proactive maintenance.

Telematics solutions enable precise tracking of routes and fuel usage, ensuring energy efficiency by reducing unnecessary fuel consumption through optimized routes. Asset monitoring helps fleet managers track vehicle utilization, maximizing vehicle deployment and reducing idle time, thus improving asset efficiency.

These technologies offer real-time tracking and monitoring of vehicles and components, helping fleet managers predict maintenance needs. RFID tags track maintenance history and spare parts inventory, while BLE sensors like FMB140, and Escort TH-BLE monitor vehicle health indicators like battery levels and engine temperatures to alert managers of issues. UWB provides accurate vehicle tracking for quick maintenance checks. These technologies reduce unexpected breakdowns, schedule timely repairs, and enhance operational efficiency by minimizing maintenance downtime and extending fleet asset lifespan.

Advanced asset monitoring solutions enhance maintenance, asset, and energy efficiencies by providing real-time insights into asset performance and health. By tracking vital metrics, businesses can make informed decisions, reduce downtime, and maximize productivity. Implementing these solutions not only saves time but also contributes to long-term savings and improved operations. MosChip® designs asset monitoring solutions that leverage advanced IoT, AI, and data analytics to provide real-time tracking, predictive insights, and seamless integration for enhanced asset management. Our solutions are customized for various industries to monitor their mobile and static assets, improving overall operational efficiency and decision-making.